Choose a Store

- Shop All

- Replacement Parts

- Performance Parts

- Accessories

- Oil & Fluids

- Special Offers

- Speed Perks

- Advice & How-Tos

- Project Guides

Share

Loading...

How Would You Like To Get This Item?

Store Pickup

Same Day Home Delivery

Home Delivery

Product Information

Product Details

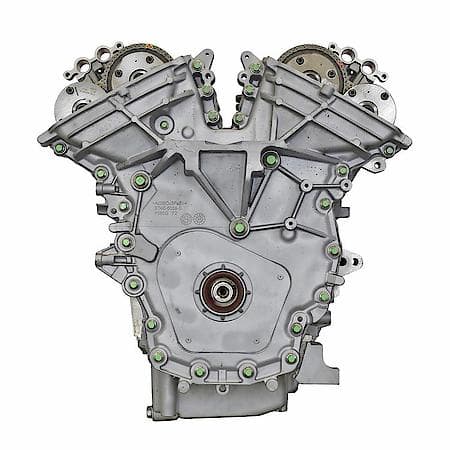

Part No. DFM22

Warranty Details (WARRANTY INFO AVAILABLE ON REQUEST)

Your remanufactured engine is tested in several specific ways after being assembled. Multiple Pressure tests. Each component is carefully checked after being cleaned to see if cracks or other defects exist in the casting. After being assembled, we pressurize the water jacket with 30 Lbs. of air pressure. As a result of these tests, you can be sure your unit will not have coolant leaks. SIM test, After pressure testing, our final check of engine performance is a spin test. We turn the engine at 400 RPM with oil pressure lines attached. The test measures compression on each cylinder, oil pressure, oil flow and allows an easy visual check that oil is reaching all critical areas. This test also allows the rear main seal to be checked for leaks. We produce most engines as long block assemblies that ship with a finishing gasket set and a new oil pump.

Product Features:

Product Features:

- Each engine we remanufacture is essentially reverse engineered - in part to discover original factory deficiencies. If possible, our seasoned R&D personnel & QC experts make improvements. Why shouldn't our engine last longer than your first?

- Engines come with installation gasket set & oil pump unless noted otherwise. If we have important installation information it will be included on tags or in the paperwork packaged with your engine.

- Engines are securely packaged in a recyclable container that will also protect your core on the return trip. Our nationwide warehouse network means speedy delivery.

- Each engine is remanufactured with quality OE level components not "white" box generic parts that may or may not satisfy your needs and expectations. When you use the best you get the best results and satisfaction.

Specifications

Engine Manufacturer Code:

DG494AA, DF592AA (Broadcast)

Flexplate Included:

No

Flywheel Included:

No

Fuel Type:

Gas

Grade Type:

Premium

Harmonic Balancer Included:

No

Main Bearing Cap Bolt Quantity:

2

No results

Feedback

Be The First To Know About Deals And Promotions.

Plus, create an account to receive $5 off of $20 or more.

TOP REPLACEMENT PARTS

ROUTINE MAINTENANCE PARTS

CUSTOMER SUPPORT

ABOUT US

PROFESSIONAL SHOPS