“Float like a Cadillac, sting like a bimmer." That may not have been the original phrase, coined by Muhammad Ali, but automotive enthusiasts like the pun. Cadillacs are luxurious to ride in, and BMWs inspire confidence when the roads get twisty. All thanks to the modern suspension system.

Cars have come a long way over the past century or so, especially when it comes to how they handle. Let's take a look at just how far.

Early Shock Absorbers

Have you ever heard the phrase “This thing rides like a buckboard?" Similar to many of today's pickup trucks, early suspension setups utilized leaf springs, several layers of steel sheets that are shackled together to create a spring. Leaf springs are still used in a lot of off-road or heavy-duty applications because of their rugged nature and ability to suspend heavy loads. A smooth ride? It's not their strong suit. The first shock absorbers were much different than what you'll find on your car today. While today's units are tubular in design and house a piston that moves through hydraulic fluid, the first shock absorbers were merely a lever with rubber pads between the frame and the leaf spring. The first cars to employ this setup were said to provide a “magnificent" ride — try one today and your kidneys would likely disagree.

Today's Shock Absorbers

Depending on what kind of car you drive, you've either got shock absorbers or struts. Struts are basically the same thing as shocks but are part of a different setup and are generally used on front-wheel-drive cars. The MacPherson Strut, named after the General Motors engineer who invented them, are housed inside a coil spring and attached to the upper control arm of a front-wheel-drive car. In the rear, they're also inside a coil spring and are bolted to the strut tower housing.

Coil springs have been around since before 1800 and didn't require lubrication like leaf springs did (to avoid getting squeaky), but they weren't combined with a shock absorber inside the spring until MacPherson gave it a try. The basic principle of the shock absorber has remained the same for decades. Monroe, a major manufacturer of shock absorbers, produced the first OE shocks in the 1930s. Today's most advanced shocks utilize the same theory but use modern technology to enhance their versatility.

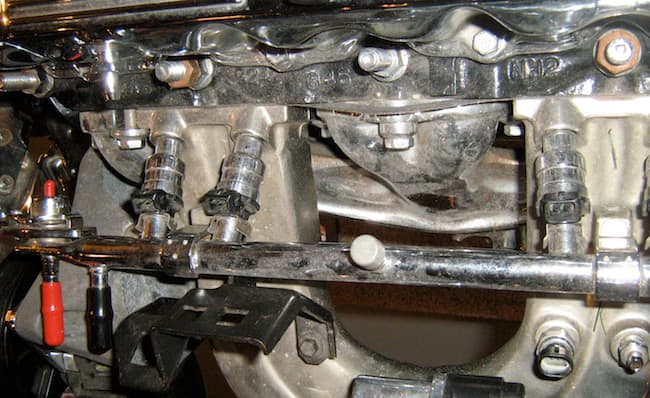

Typically, the piston within the shock housing or tube has small holes or passages in it that the oil is forced through as the piston moves through the tube. This dampens the up-and-down motion of the tires as you go over the road. The primary goal of the shock is to prevent your tire from leaving the ground. If it doesn't do that, the ride gets really rough and the car becomes hard to control. Many of today's shocks use multiple valves, electronics, or even magnetism to adjust how they behave over certain terrain or driver preferences.

Does your car have sport mode? Pressing that button on a car that has adjustable suspension changes the way the valves in the shock respond, increasing the firmness of the ride and improving your cornering ability and control. Some of the first cars to use electronics in how their suspension responded had sensors in the front bumper that would send a signal to adjust the ride from firm, medium, or soft, depending on road conditions.

Today's most recent innovation in shock technology can be found in the new 2017 Ford Flex. Similar to the early method, the Flex has sensors in the front area of the car that can react to poor road conditions like the dreaded pothole. The sensor will actually send a signal to the computer and lift the strut just enough to lift the tire off the ground, essentially passing over the pothole without spilling your morning coffee. Whether you want to “float like a Cadillac" or “sting like a Bimmer," many of today's cars can serve up both with the push of a button, unless your shocks have gone bad. Most shock absorber manufacturers recommend replacing them at 50,000-mile intervals.

Have you had experience with some of the older shocks? Tell us about it in the comments!